VONK is proud to start a Virtualization and DCS upgrade project in the Niger Delta in Nigeria. VONK is responsible for the PCD/IT rejuvenation of this complex project. Our client SPDC is having multiple gas gathering stations to deliver gas to the NLNG plant on Bonny Island. The gas gathering stations are being controlled by a Distributed Control System. The various DCS systems are outdated and need to be upgraded without stopping the plants production. VONK will retrieve information from the existing systems and will do the detailed design till commissioning on site for the new systems. We will implement a virtual system allowing to have the latest technology available for cyber security and creating the possibility to do remote maintenance on the connected systems.

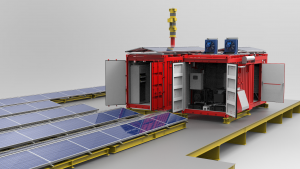

VONK is proud to announce that we have received the contract to deliver and install the Emergency power for a Liquefied Natural Gas plant in Brunei. The contract entails 3 units with extreme fire and explosion demands.

The power generation unit will be placed in a container placed on the ground floor and the power distribution unit will be placed on top. This so called stacked design reduces the required plot space significantly and is very suitable for sites with space constraints. The units will be manufactured and tested fully, prior to transport to the site location. This allows a plug and play startup of the units, saving time and cost for our client.

The project will be executed by team having office in our facilities in Brunei. The site installation and construction activities will be executed together with our local Partner Zainal Daud.

VONK has developed a renewable temporary off-grid power solution to deliver ‘green’ power to offshore wind turbines while they are under construction.

The unit typically consists of a small solar farm, battery storage, a very small back-up diesel generator, a power management system and a remote control system.

Furthermore small wind turbines suitable for the harsh offshore environment can be added and the entire package complies with offshore regulations.

The units are reusable, plug and play, low cost, easy to transport and suitable for most offshore wind turbine designs.

The temporary off-grid power solution is low-maintenance, limits tug boat movements, reduces operational cost and eliminates heavy diesel consumption during construction of an offshore wind farm. Thus contributing to a fossil fuel free approach of wind farm operators.

We can offer rental / lease options too.

VONK EUA designed and manufactured a Heat Tracing Distribution System for an Onshore Processing Facility for one of our Far East clients which are almost ready for dispatch.

This project is to provide Heat Tracing Distribution Panel in an Auxiliary Substation at the client’s facility. These Heat Tracing Panel will be identical to 200 existing Heat Tracing Distribution Boards which have been delivered by VONK back in 2009. Two additional pieces of Hazardous area, ATEX Zone 2, Enclosure for Remote Single RTD multiplexer units will be delivered too.

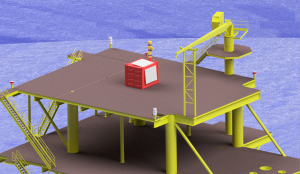

VONK has developed a fully self-supporting cost effective decommissioning skid for offshore application. These units can be deployed at offshore subsea wells that are operationally end of life. The almost maintenance free skid is powered by a renewable energy source fed by solar and includes a small diesel driven back-up generator that ensures almost no SOx and NOx emissions and require little or no refueling. The skid powers the built-in process monitoring and control systems as well as the navigational aid systems for offshore platforms and is featured with remote alarming and control. The system can be configured to your specific requirements. Moreover VONK offers also options to lease or rent equipment depending on your need.

Leman Bravo has been the second platform that has been de-complexed and supplied with a VONK Hybrid-Power Solution designed, produced, and commissioned by VONK.

The development of this project started approximately one year ago. It started out with the design, construction, and testing of the VONK Hybrid-Power Solution in Coevorden. Then the Hybrid-Power Solution was transported to its destination in the North Sea, near the coast of England.

After installation, VONK commissioning engineers have supervised Shell personnel with the commissioning of the system.

It is now intended to run without maintenance or intervention for the upcoming year, as the Leman Echo is already performing. Leman Delta has been developed and is awaiting transportation to sea.

VONK is looking forward to assist with the upcoming Hybrid-Power projects.

VONK has been conducting training sessions with the engineering and operations teams of the NAM and Shell UK. The third and most recent training session was November 5th, 2018 participated by the assets RPE’s.

The goal of the training sessions is to familiarize with the Leman Hybrid Power system, which was commissioned by VONK back in 2016. The Leman Hybrid Power Project is an intelligent system that slightly deviates from the Shell standard energy systems providing a lot more functionalities.

In order to familiarize the teams of the NAM and Shell UK, VONK has come up with a training course which will teach the team how to work with this unique system. The training consists of theory and practice session and during the practice session the team members will learn how to deal and how to solve issues on-site, but also from remote, keeping up the functionality of the system.

VONK is proud to continue our work with the NAM and Shell UK.

VONK commissioning team will be travelling to Alexandria, Egypt, on the 14th of November for the commissioning of the EPC metering system.

The previous metering system was successfully delivered by VONK back in 2001, but has now become obsolete and is due for an upgrade in 2018.

A metering system is a supervisory system for liquid and gas flow measurement. These systems may sometimes communicate with flow computers, as in this case.

For the new system VONK selected to use the latest technology in the form of the ABB FlowX, a highly accurate and certified flow computer.

VONK will conduct the migration of the metering system under live plant conditions to ensure production is maintained for our client Badr El-Din Petroleum Company (Bapetco) .

VONK is very proud to be continuing our successful project delivery with BAPETCO In Egypt.

VONK has been awarded a contract with Bapetco in Egypt. The Bapetco Bed 3 plant is a gas compression/treatment station for the production of gas which feeds the power plants that supply electricity to the grid of Egypt. This implies that availability and uptime of the plant are key.

The production equipment is being renewed and expanded which requires a new electrical infrastructure. VONK will execute a study to renew the electrical infrastructure supplying the new demanded power. The implementation shall be phased by making use of opportunity shutdowns per unit.

VONK is pleased to announce that it has formalized its Cooperation Agreement with Wehaya, a Bumiputera Engineering Company in Malaysia. Wehaya is mainly known for its Maintenance, Installation and Construction activities in the disciplines E&I and C&A in the Malaysian Oil & Gas market.

In the cooperation, VONK will add value by jointly executing complete projects, including: Hybrid Power Facilities, Brownfield C&A plant upgrades, and virtualization of the plant’s control systems.