Control & Automation

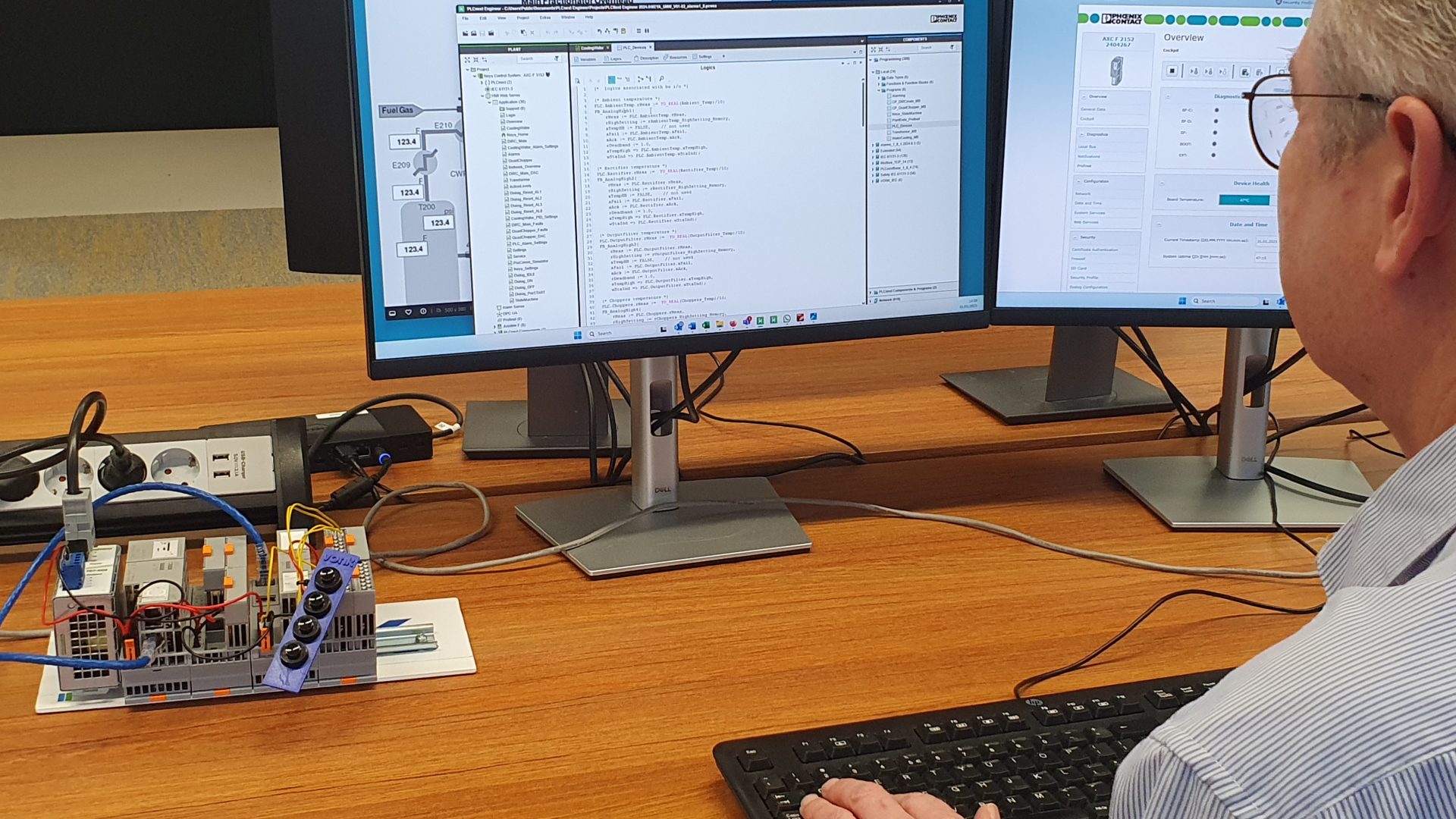

VONK has a long history of implementing large scale automation systems controlling the core processes of our client’s production plants. Being independent of any brand of Programmable Logic Controllers (PLC), Emergency Shutdown Systems (ESD) or Distributed Control Systems (DCS), we proved our ability to integrate various systems into a full functional plant. It is of paramount importance to truly understand the various brands of systems and subsystems to manage the interfaces and prevent pinpointing in case of issues between the various suppliers. Our clients put the trust with VONK to upgrade their automation systems after years of successful operation to exchange to the latest technology, without creating a plant shutdown.

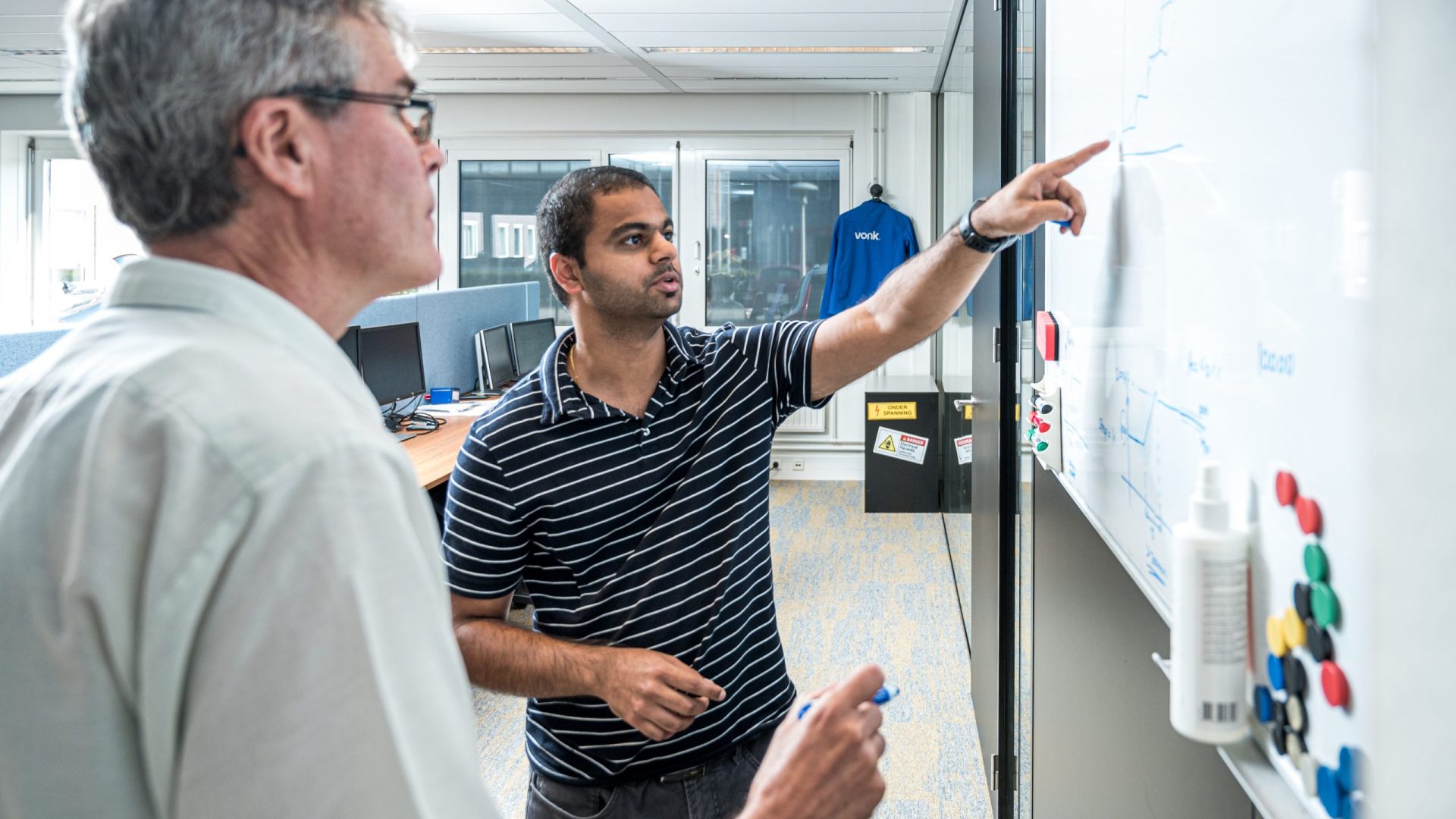

Why VONK as your System Integrator?

Precision Upgrades & Seamless Integration

VONK has executed numerous upgrades and rejuvenations in capital-intensive industries, where halting operations would be highly costly. Trusted with the core of the system, VONK serves as a dependable “surgeon,” performing critical “heart transplants.” With a proven track record, VONK is your reliable partner.

In addition, VONK has delivered numerous containerized control buildings, including the integration of control and automation equipment. Beyond installation, we also have the expertise to program, test the equipment, and manage various interfaces, ensuring seamless operation.

Cisliano: Upgrading the Complete Automation Systems of a Lube-Oil Plant

Our client has successfully operated their lube oil plant for decades. However, the Control & Automation (C&A) systems had become outdated, making maintenance increasingly difficult and costly, while also heightening vulnerability to security threats. VONK conducted a thorough study, providing several options for the plant’s future operation while minimizing production losses.

Following the study and consultations between the client and VONK, a solution was selected based on cost, downtime, and future support potential. VONK then managed the execution of the upgrade using Italian-speaking engineers to assist operators in adapting to their new environment. The upgrade incorporated the latest technology standards while maintaining practical continuity in the plant’s processes.

Bruneian clever combinations

A gas production operator upgraded the technology on their production platforms to the latest standards while transitioning their power systems to fully sustainable energy. The platforms now operate using solar panels during the day and batteries at night.

VONK delivered a complete package, including DCS control systems, safety systems, and PLCs for managing the power systems. This approach saved millions and significantly reduced the platform’s OPEX, with maintenance intervals extended to once every two years.

The client expressed their appreciation, noting that the project was one of their most successful, delivered on schedule, within budget, and meeting all specified quality standards.